kayla941

08.02.2021 •

Mathematics

You work for SteelPro a fabrication company that specializes in machining specialty alloys. One of your best customers is Bombardier Transportation. Bombardier has asked you to fill an order for 20 of their part 107. Bombardier will pay you $500 for each good part 107 bu twill only accept exactly 20 good ones- no more, no less. The raw materials required to make a 107 cost $150. Unfortunately, you have yield loss issues related to manufacturing the 107. Assume that the 107s are produced independently of each other with the probability of an individual 107 being good being equal to 0.85. Defective 107s can can be scrapped for $50. There is also the technical challenge that the way you process the 107s is that you machine the entire batch (whatever batch size you choose) and then you heat treat and further process them and only after the heat treating and further processing do the defects become detectable. Thus, you must determine the batch size to run prior to knowing what your precise yield will be.What is the minimum number of 107s you need to schedule to have a 0.90 probability that you get 20 good 107s?

Solved

Show answers

More tips

- S Style and Beauty Unbelievable Hairstyles for Long Hair - 2021 Trends...

- H Health and Medicine How to Whiten Teeth and Get the Perfect Smile...

- F Food and Cooking How to Make Thin Pancakes: Recipe and Tips...

- S Style and Beauty Is Hot Scissor Haircutting Beneficial or Dangerous?...

- S Style and Beauty How to Get Rid of Under Eye Bruises?...

- F Food and Cooking Is Bacon Good for You?...

- S Style and Beauty Discover the Art of Nail Design: How Do You Paint Your Nails?...

- P Philosophy How to Develop Extrasensory Abilities?...

- O Other Everything You Need to Know About Kudyabliks...

- C Computers and Internet The Twitter Phenomenon: What it is and How to Use it...

Answers on questions: Mathematics

- M Mathematics Use the graph to predict the number of CDs the students at your high school bought in 2008...

- H History American citizens may belong to __ interest groups at one time. a.) no more than four b.) as many as two c.) any number of d.) as many as three...

- E English • What is the best or worst job you have ever had? Give examples of what made it the best or worst job....

- S Social Studies What were some things colored people couldn t do during the segregation time period?...

Ответ:

0.0473

Step-by-step explanation:

Given : The proportion of gambling addicts : p=0.30

Let x be the binomial variable that represents the number of persons are gambling addicts.

with parameter p=0.30 , n= 10

Using Binomial formula ,

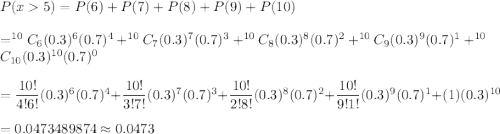

The required probability =

Hence, the required probability = 0.0473